Selective Solder Pallet with Removable Crossbar

Selective Solder Pallet with removable crossbar. Spring loaded plungers hold components in place. Threaded inserts are also used to fasten the PCB to the pallet, ensuring flux and solder will not flood the tool. The back of the solder pallet is slotted, chamfered and pocketed to help the solder flow into smaller openings.

Selective Wave Solder Fixtures

With MB Manufacturing’s continuous improvement strategy we have developed the ultimate selective solder fixture out of a combination of titanium and composite, incorporating the latest in flow technologies to eliminate skips and bridges on a selective solder pallet that will last for years in a high production environment.

Our Selective Wave Solder Fixtures increase productivity and reduce defects on your mixed technology boards.

Selective Solder Fixture w Cross Bar

This Selective Wave Solder Pallet has a hinged cross bar with spring plungers and pressure pads to prevent parts from lifting or tilting in the wave solder process

Special Components - Locating Bar

Selective Solder Fixture with Special Component Locating Bar

MB-Mfg now introduces state of the art component holddowns and support bar mechanisms. The solder pallet features quick simple loading of parts. Holding components to extremely accurate heights of the PCB, while maintaining a 90 degree orientation to the circuit board.

Selective Solder Pallet w Crossbar

This selective solder pallet features a removeable crossbar and was made for a high volume PCB to be run on a Seho Wave Solder Machine.

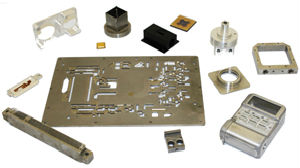

Selective Solder Fixtures

Selective solder fixtures protect bottom side SMT components & eliminate the risk of loosing parts in the solder.

Over 27 Years of Innovation

A leader in the electronics industry, providing unsurpassed expertise.

Quality assurance - Mission accomplished

We engineer, manufacture, and assemble all your custom PCB assembly tools.

Fastest delivery in the industry!

Our friendly staff is always available to assist you - 24 hour quoting.

ENGINEERING THE IMPOSSIBLE

ENGINEERING THE IMPOSSIBLE