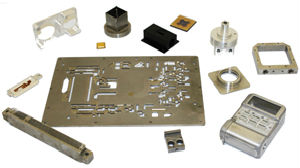

Selective solder fixtures protect bottom side SMT components & eliminate the risk of loosing parts in the solder.

Our unique designs will eliminate skipping and bridging.

- No need to tape areas which reduces operator time and speeds up your line.

- Fixtures available in Titanium, composite material (ROHS compatible) or a combination of both.

- Affixes through-hole components and large parts that must be masked on the bottom side on a fairly heavy printed circuit board.

- Thin wall areas protect SMT components as little as 0.020 in. from through-hole components.

- Millouts for heavy ground-plane areas allow the board to reach temperature and solder properly.

- Combination of composite, which minimizes heat sinking, and titanium, to permit extremely thin walls between SMT parts and through-hole parts - down to 0.01 in. clearance - and still get effective solder.

- A fixture used to very accurately locate (height and width wise) the row of connectors on a circuit board or panel.