About Us

At MB, we design to maximum simplicity and ease of use. On the manufacturing floor, we find this works best.

At MB, we design to maximum simplicity and ease of use. On the manufacturing floor, we find this works best.

We custom design selective and wave-soldering on the board as determined by how the board is designed, the location and shape of openings, how the board is supported, and other factors. Millouts for heavy ground-plane areas allow the board to reach appropriate temperature and solder properly.

We approach every fixture design with the goal of developing the simplest solution that serves the purpose. Features that add value must be simple and cost-effective.

Your PCB assembly obstacle may not be such a problem.

In fact, it could be an opportunity. Especially if your competitors are having difficulty too! Come to MB!

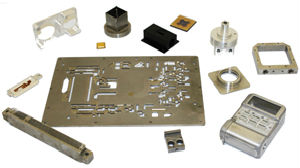

MB Manufacturing design and develops adjustable and custom fixtures for wave and selective soldering, auto-insertion, pick and place, and other electronics production operations.

Tougher jobs done even better.

Use of ever shrinking components on increasingly dense printed circuit boards – dunked into the higher temperature processes associated with RoHS (lead free) soldering 0 all this causes continuing challenges and problems in printed circuit board assembly and production.

Where manufacturing challenges meet surprising design solutions.

Often, it’s a specific manufacturing problem that brings our fixture design group into the picture.

A short time later, the customer finds it surprising that their custom MB fixture goes far beyond solving the problem at hand, to improving the efficiency and productivity of the process altogether.

Over 27 Years of Innovation

A leader in the electronics industry, providing unsurpassed expertise.

Quality assurance - Mission accomplished

We engineer, manufacture, and assemble all your custom PCB assembly tools.

Fastest delivery in the industry!

Our friendly staff is always available to assist you - 24 hour quoting.