MATERIAL SAFETY DATA SHEET

CDM 68.630 and 68.650 – SPECIFIC RISKS

Not applicable as curing this material ensures that the compounds remain reasonably stable under normal use as specified in the technical data sheets, which should be adhered to.

As far as EEC and French regulations are concerned, this material is not submitted to labeling compulsory for dangerous products or materials containing hazardous components.

SECTION I – IDENTIFICATION

- Product Name: CDM 68.630 and 68.650

- Supplier: Manufacturer

- Importer

- Distributor / Agent

- Dpt to be contacted

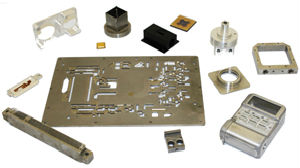

- Intended Uses: Material for applications in electronics

- Others: Not applicable

SECTION II – CHEMICAL COMPOSITION

- Chemical components included in the formulation of the product (and which could be hazardous to health). Not applicable in normal conditions of use.

- Impurities (which might be hazardous to health): Not applicable.

- Others: Laminate made up from a glass mat substrate impregnated with an epoxyde resin, fully cured.

SECTION III – PHYSICAL PROPERTIES

- Physical state: Solid (panels or sheets)

- Temperature Characteristics:

- Solubility: Insoluble in Water

- Density: 1.85 g/cm³ at 20° C

- Others: Color: light yellow / blue

- Odorless

SECTION IV – STORAGE AND HANDLING

- Handling and storage precautions: Not applicable

- Packing material: a) recommended: Not applicable b) to be avoided: Not applicable

- Dangerous reactions possible with: Not applicable in normal conditions of use. In case of small quantities of halogenous, sulfurous and azotic gas be emitted.

- Products / Materials whose decomposition might be dangerous: Not applicable.

- Individual protective measures: When handling this material, wear protective gloves. During machining processes, inhalation of dust is to be avoided and protective clothing-mask, glasses, and gloves should be worn in the even of there being no global protective equipment installed.

- Special protective measures: During machining, it is recommended that the dust be extracted at the point of emission.

- Measures to be taken in case of accidental spillage or leakage: Not applicable.

SECTION VI – FLAMMABILITY AND RISKS OF EXPLOSTION

- Flash point: Not applicable

- Spontaneous inflammation point (1 degree C). This material is not inflammable in normal conditions of use. However, in case of use in abnormal conditions at extremely high temperatures (>500° C), the organic compounds could react causing the material to ignite.

- Particular dangers of fire or explosion (residual decomposed product resulting from pyrolyze). In the even of combustion, various flammable organic compounds might be emitted.

- Methods of extinguishing fire:

- Special protective measure in case of fire:

- Avoid inhalation of fumes

- Wear a special respiratory device

SECTION VI – TOXICOLOGICAL INFORMATION

- No specific risks under normal conditions of use. During machining process, dust may cause irritation to the skin and the mouth by abrasion

SECTION VII – EMERGENCY / FIRST AID ACTION

- Incase of irritation, wash thoroughly with water.

- Incase of eye or respiratory system irritation, a doctor should be consulted.

- Incase of accidental ingestion of a large amount of dust; seek medical advice. DO NOT INDUCE VOMITING.

SECTION VIII – ENVIRONMENTAL PROTECTION

- Dust originating from machining processes and from the material itself should not be disposed of in water or in the open air.

- The entire waste products should be collected and disposed of in line with regulations, in incineration plants or buried in approved sites.

THIS DATA IS OFFERED IN GOOD FAITH AS TYPICAL VALUES AND NOT AS A PRODUCT SPECIFICATION. NO WARRANTY, EITHER EXPRESSED OR IMPLIED, IS HEREBY MADE. THE RECOMMENDED INDUSTRIAL HYGIENE AND SAFE HANDLING PROCEDURES ARE BELIEVED TO BE GENERALLY APPLICABLE. HOWEVER, EACH USER SHOULD REVIEW THESE RECOMMENDATIONS IN THE SPECIFIC CONTEXT OF THE INTENDED USE AND DETERMINE WHETHER THEY ARE APPROPRIATE.