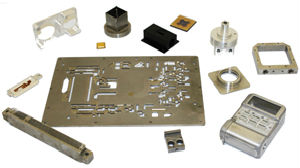

Designed to eliminate solder skipping, drag out, and add better connector support.

Our custom engineered Dedicated Wave Solder Fixtures are designed to eliminate solder skipping and drag out, add better connector support and provide excellent ground plane and gold finger masking. Our materials provide unmatched flatness and eliminate delimitation. Titanium material can also be used for this type of fixture offering longer pallet life, eliminating warpage and masking SMT's that are extremely close to thru holes.

- PCB's can be located accurately with titanium pins for manual and auto insertion.

- Components can be accurately held down and located on your PCB's to within .003".

- Features slides to hold and accurately locate over hanging components.

- Removable cross bars with spring loaded pressure pads to hold components down.