Required Customer Information

2D .dxf files in AutoCAD 2009 and lower, or .iges, .sat, are all that are required.

This will expedite the data transfer and quoting processes as well as the production lead times.

Include text with the following information:

- Part number

- Type and thickness of fixture material

- PCB dimensions and thickness

- Bottomside component height per layer

- Quantity ordering

- Any other pertinent information necessary for designing your fixture

MB-4000 Black& MB-6000 Green

MATERIAL SAFETY DATA SHEET

Valid from March 2000

- Identification of the substance/preparation and of the company/undertaking.

MB-4000 Black

Manufacturer: MB Manufacturing, Inc.

1 Gwinnup Road

Blairstown, NJ 07825

Telephone: (908)-362-5588 - Composition/Information on Ingredients

Chemical characteristics: Solid laminate made of glass fibers, epoxy resin and fillers cured under pressure and high temperature.

Carcinogenic Substances: Neither the base product nor any of the additives are known to be carcinogenic.

Fiberglass Nuisance Dust Exposure: OSHA PEL = 5 mg/m³ (resp): 15mg/m³ (total), ACGIH TLV = 5mg/m³

- Hazards Identification

Dust from dry fabrication operations can sometimes cause mechanical irritation to skin and less frequently to eyes. Maintain normal good housekeeping.

- First Aid Measures

Contact with Eyes: This product is in solid sheet form. Always use proper eye protection when cutting or machining this material. In the event that dust or particles contact the eyes during subsequent machining or cutting, administer eyewash in same manner consistent with company safety policy and consult physician. The particles are not considered to be otherwise hazardous. Proper ventilation of fabrication dust is recommended. (see comments under #7)

Inhalation: If dust from dry fabrication operations is not properly exhausted, a facial respirator mask should be worn for nuisance dust. (see comments under #7)

- Fire Fighting Measures

Suitable Extinguishing Agents: Water, foam, dry powder, CO2, Halon

In Case of fire, the Following Hazardous Gases can be Produced: CO2 and CO

Special Protective Equipment: For major fires, self-contained breathing apparatus and personal protective equipment may be needed. - Handling and Storage

No particular requirements for handling or storage of this product.

- Exposure Controls/Personal Protection

General Protective Measures: No protective clothing is required for handling this product itself.

Dust Generated During Machining: Correct industrial practice should be followed, with extraction equipment on the machine (extraction speed = 22 m/s). Alternatively, a dust mask should be worn. Safety glasses are recommended.

- Accidental Release Measures

None Required

- Physical and Chemical Properties

Appearance:

Form

Solid

Odor

Odorless

Color

Black or Green

Specific Gravity: 1.85

pH Value: N/A

Boiling Point: N/A

Decomposition Temperature: >500°C

Flash Point: N/A

Ignition Temperature: N/A

Explosion Hazard: N/A

Vapor Pressure: N/A

Solubility: Non Soluble in Water or Oil

Partition Coefficient: N/A

- Stability and Reactivity

Stability: Product is stable.

Hazardous Reactions: No hazards known.

Hazardous Decomposition Products:

CO:

<7 g for 100 g of Durostone

CO2:

<60 g for 100 g of Durostone

HCI:

<0 g for 100 g of Durostone

HBr:

<0 g for 100 g of Durostone

HCN:

<0 g for 100 g of Durostone

Others

<.01 g for 100 g of Durostone - Toxicological Information

Remarks: According to experience, this product is considered to be harmless to health if handled in the correct manner.

- Ecological Information

Disposal: This product can normally be disposed of as normal solid waste for landfills. However, we hold no liability for disposal of this product. It is the user responsibility to comply with all local and state laws for proper disposal. Always consult the local regulatory agencies for proper disposal. This product is not bio-degradeable.

Remarks: The product is insoluble in water. Specific tests have not been run on this specific product, but it is not expected to be harmful to fish or bacteria. Always comply with local regulatory agencies for rules on proper disposal.

- Transport Information

This product is considered non-hazardous and can be transported as such.

- Regulatory Information

None specified. Always check with local authorities.

- Other Information

The technical staff at MB Manufacturing, Inc. believes this information to be true and accurate for the normal and intended use of this product as of the date that this MSDS sheet was produced. Since we have no control over the actual use of this product, it is the sole responsibility of the user to determine the proper protection with regards to safety and disposal of this product. MB Manufacturing, Inc. further recommends consulting local regulatory agencies to determine applicable laws and regulations.

Delmat

Delmat Material has excellent machinability and will maintain mechanical properties at soldering temperatures. This material will not pick up solder and is resistant to the chemicals in flux and solvents, including MEK and acetone. Tests conducted with temperature profiling devices show an even thermal distribution across the PCB. The monolithic sheet construction of Delmat means it will not delaminate when exposed to repeated chemical and temperature changes.

|

Technical Data

|

|||

|

English Units

(Metric Units) |

Delmat

68.650 |

Delmat

68.610 |

Delmat

68.640 |

|

Grade

|

Standard

|

Anti-Static

|

Anti-Static

|

|

Color

|

Blue

|

Black

|

Grey

|

|

Density (g/cm³)

|

1.85

|

1.85

|

1.85

|

|

Water Absorption

|

< .20 %

|

< .20 %

|

< .20 %

|

|

Coefficient of Linear Expansion (k –1)

|

64 10 –6

|

64 10 –6

|

64 10 –6

|

|

Thermal Conductivity (BTU/ft h F)

|

Low

|

Low

|

Low

|

|

Continuous Operating Temperature

|

Less than 300°C.

|

Less than 300°C.

|

Up to 300°C.

|

|

Specific Heat Capacity (J/GxK) Between 20° C and 200°C

|

0.90 to 1.15

|

0.90 to 1.15

|

0.90 to 1.15

|

|

Thickness’ Available

|

0.118”, 0.198”, 0.236”, 0.315”, 0.394”, 0.472”

(3-5-6-8-10-12MM) |

||

|

Tolerances on Thickness, Flatness and Parallelism

|

< .394” ± .004”, .472 ± .006”

(< 10MM ± 0.10MM, 12MM ± .15MM) |

||

Note: The typical average values shown above are the results of extensive laboratory tests.

MB Mfg. cannot accept responsibility for any particular application of the material.

68.630 & 68.650

MATERIAL SAFETY DATA SHEET

CDM 68.630 and 68.650 – SPECIFIC RISKS

Not applicable as curing this material ensures that the compounds remain reasonably stable under normal use as specified in the technical data sheets, which should be adhered to.

As far as EEC and French regulations are concerned, this material is not submitted to labeling compulsory for dangerous products or materials containing hazardous components.

SECTION I – IDENTIFICATION

- Product Name: CDM 68.630 and 68.650

- Supplier: Manufacturer

- Importer

- Distributor / Agent

- Dpt to be contacted

- Intended Uses: Material for applications in electronics

- Others: Not applicable

SECTION II – CHEMICAL COMPOSITION

- Chemical components included in the formulation of the product (and which could be hazardous to health). Not applicable in normal conditions of use.

- Impurities (which might be hazardous to health): Not applicable.

- Others: Laminate made up from a glass mat substrate impregnated with an epoxyde resin, fully cured.

SECTION III – PHYSICAL PROPERTIES

- Physical state: Solid (panels or sheets)

- Temperature Characteristics:

- Solubility: Insoluble in Water

- Density: 1.85 g/cm³ at 20° C

- Others: Color: light yellow / blue

- Odorless

SECTION IV – STORAGE AND HANDLING

- Handling and storage precautions: Not applicable

- Packing material: a) recommended: Not applicable b) to be avoided: Not applicable

- Dangerous reactions possible with: Not applicable in normal conditions of use. In case of small quantities of halogenous, sulfurous and azotic gas be emitted.

- Products / Materials whose decomposition might be dangerous: Not applicable.

- Individual protective measures: When handling this material, wear protective gloves. During machining processes, inhalation of dust is to be avoided and protective clothing-mask, glasses, and gloves should be worn in the even of there being no global protective equipment installed.

- Special protective measures: During machining, it is recommended that the dust be extracted at the point of emission.

- Measures to be taken in case of accidental spillage or leakage: Not applicable.

SECTION VI – FLAMMABILITY AND RISKS OF EXPLOSTION

- Flash point: Not applicable

- Spontaneous inflammation point (1 degree C). This material is not inflammable in normal conditions of use. However, in case of use in abnormal conditions at extremely high temperatures (>500° C), the organic compounds could react causing the material to ignite.

- Particular dangers of fire or explosion (residual decomposed product resulting from pyrolyze). In the even of combustion, various flammable organic compounds might be emitted.

- Methods of extinguishing fire:

- Special protective measure in case of fire:

- Avoid inhalation of fumes

- Wear a special respiratory device

SECTION VI – TOXICOLOGICAL INFORMATION

- No specific risks under normal conditions of use. During machining process, dust may cause irritation to the skin and the mouth by abrasion

SECTION VII – EMERGENCY / FIRST AID ACTION

- Incase of irritation, wash thoroughly with water.

- Incase of eye or respiratory system irritation, a doctor should be consulted.

- Incase of accidental ingestion of a large amount of dust; seek medical advice. DO NOT INDUCE VOMITING.

SECTION VIII – ENVIRONMENTAL PROTECTION

- Dust originating from machining processes and from the material itself should not be disposed of in water or in the open air.

- The entire waste products should be collected and disposed of in line with regulations, in incineration plants or buried in approved sites.

THIS DATA IS OFFERED IN GOOD FAITH AS TYPICAL VALUES AND NOT AS A PRODUCT SPECIFICATION. NO WARRANTY, EITHER EXPRESSED OR IMPLIED, IS HEREBY MADE. THE RECOMMENDED INDUSTRIAL HYGIENE AND SAFE HANDLING PROCEDURES ARE BELIEVED TO BE GENERALLY APPLICABLE. HOWEVER, EACH USER SHOULD REVIEW THESE RECOMMENDATIONS IN THE SPECIFIC CONTEXT OF THE INTENDED USE AND DETERMINE WHETHER THEY ARE APPROPRIATE.

Pallet Specifications

-

Composite material: Durostone, thickness to be determined by our Engineers (3-4-5-6-8-10 or 12mm)

-

Maximum pallet size is 20”W x 30”L, maximum overall pallet height is 2.0”, unless specified otherwise by Customer.

-

Lip thickness is 0.080” +/- 0.010” on all four sides of pallet.

-

Lip width is 0.25” +/- 0.025” on all four side of pallet.

-

Maximum bottom side chamfer will always be taken per wall per aperture so as not to break thru any topside walls.

-

*Floor thickness to be minimum of 0.100” unless otherwise specified by Customer.

-

*Wall thickness to be a minimum of 0.040” unless otherwise specified by Customer.

-

Stiffeners to be made of aluminum, 0.5”w x 0.5”h.

-

Hardware for stiffeners to be made of stainless steel and assembled from top down.

-

Turn Clamps to be assembled with stainless steel hardware and will be assembled from the top down, will be spring loaded and will have black caps on top.

-

Hold down locations to be determined by MB Manufacturing.

-

Inserts for composite fixtures to be 4.40 only, unless otherwise specified, and will NOT be exposed to the wave solder.

-

Tapped holes for titanium fixtures to be 4.40, unless otherwise specified.

-

Use of crossbars specified by Customer.

-

MB-0400 style crossbars will be used with aluminum support hinge blocks for added durability.

-

Component height must be provided when using plungers or pressure pads for component hold downs.

-

Pressure pads to be made of same material as pallet and be spring loaded.

-

Crossbars with plungers must have 3-4 plungers per bar, tips to be chamfered when specified by Customer.

-

Leading and trailing edge stiffeners to be engraved with Customer tool number.

-

Pallet to be engraved with tool number, vendor name, date, and pallet serialization number.

-

All pallets are to be serialized with order quantities greater than one.

-

Certificate of Compliance to be delivered with all fixtures.

-

Copy of final drawing to be delivered with the fixture.

-

Bottom of pallet to be slotted to reduce the effects of outgassing, to be milled in the direction board runs when possible. Criss-cross design to be used when Customer specifies deems necessary.

-

Finger slots to be added on pallet to aid in PCB removal.

-

Final approval is given upon receipt of Purchase Order number.

-

All fixtures will be properly packaged.

*Pertain to Selective Solder Fixtures Only

Over 27 Years of Innovation

A leader in the electronics industry, providing unsurpassed expertise.

Quality assurance - Mission accomplished

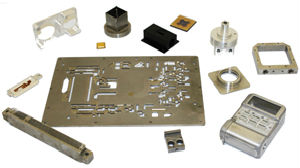

We engineer, manufacture, and assemble all your custom PCB assembly tools.

Fastest delivery in the industry!

Our friendly staff is always available to assist you - 24 hour quoting.