By Mark Beesley, MB Manufacturing Inc., Blairstown, NJ

One of the great challenges in the electronics industry is to push the envelope as to what can be accomplished. Fixturing helps bridge technology leaps, as well as solve old technology blunders.

Time and money do not always afford us the convenience of building the perfect Printed Circuit Board design with the perfect production tools but fixturing can often fill the gaps and make possible the impossible.

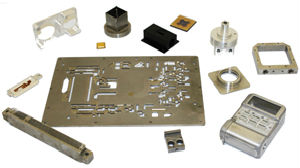

Before superior materials were developed carriers were made of hard coated aluminum, fiberglass and phenolics. Primary uses here were holding odd shaped PCB’s, providing additional PCB support and holding components in place. While these issues are still important other issues have come to the forefront. With the introduction of Surface Mount Technology came new high temperature electrostatically dissipative epoxy and polyester materials, bringing a solution to new challenges in the industry.

Fixture design has been called an art but I don’t believe the industry would have grown in leaps and bounds for a fixtures’ art appeal. It must function well NOT look nice. Through trial and error as in any scientific experiment some fabricators have developed proven scientific methods for pallet design. Flow dynamics, equipment capabilities, chemical and electrical properties all play a part in developing a good Process Carrier design. This is critical in eliminating skipping, bridging, warping and component lifting.

Many people believe if a PCB is properly designed for manufacture it eliminates the need for fixturing. This assumption is correct but it can also be said “With enough time and materials I could build a battleship”.

Fixturing can be an economical solution to many PCB design problems. The knowledgeable fixture designer will understand the requirements of the project and bring financial success to an otherwise costly predicament.

Contributions of Process Carriers (Fixturing) in a Constantly Evolving Electronics Industry

Some practical uses of Process Carriers are the protection of PCB’s from damage caused by handling, elimination of spot masking or taping to protect areas on PCB from solder and reducing or eliminating warpage of thin or heavily populated PCB’s. Process Carriers provide support and heat protection on flex circuits and ribbon cables. Carriers can not only reduce the need for new equipment but can enhance existing equipment. In a high mix, low volume production line carriers are invaluable in increasing productivity and decreasing labor expense by being manufactured to the maximum conveyor width, eliminating the need for machine conveyor adjustments on each run.

On a Selective Solder machine it’s difficult to solder near the edges of PCB on conveyor sides, thus making the carrier a must to move the PCB away from conveyor belts.

Selective Solder Equipment vs. Selective Solder Fixtures

With the increase in double sided mixed-technology PCB’s a good process for fabricating these boards had become more critical. There have been many articles written describing alternative methods for this process, mainly equipment manufacturers promoting a new expensive machine to do the job. Depending on the particular application, in some cases equipment may be a better alternative but this should be examined based on the following three considerations.

1). Board Design

The design of a board can sometimes be changed to eliminate the need for carriers. For example, adding breakaway edges to hold odd shaped boards. The problem with this may be not having enough time to redesign the PCB or this option may be too expensive. Or, as in the case of EMS Manufacturing, not your choice.

2). Production Needs

Should I buy special equipment to run the PCB’s without a carrier? As in the selective soldering of double sided mixed-technology boards, selective soldering machines have come a long way but their pricing can sometimes be prohibitive. There is also the added expense of paying someone to program each PCB to be soldered. This equipment as well as a carrier has limitations as to how close a thru hole component can be to an SMT component being masked.

If the PCB has a medium to high pin count this equipment cannot compete with the speed of a wave soldering machine. Nor will this equipment provide PCB support to prevent warpage, or hold down components that lift or tilt, nor will it hold odd shaped PCB’s. Soldering near the edges of PCB or having overhanging components also present problems along PCB edges that run on the conveyor.

Flow dynamics play less of a role, eliminating some of the process variables using selective solder machines. Some selective solder machines do allow good process control creating repeatable results once a good recipe has been developed.

Another main advantage of selective solder equipment is the ability to solder thru hole components when there are bottom side components taller than .250”. This is a limitation of pallets because most wave solder machines have a difficult time soldering PCB’s more than .250” from the bottom of the fixture although it has successfully been done up to .500” with the right wave solder machine.

3). Application Review

Will a Process Carrier allow me to produce PCB’s cost effectively, lowering or better yet eliminating defects, reducing labor and increasing efficiency? In some cases the answer falls in a grey area. Some fabricators have developed process carriers that can do all of the above and through science have learned the limitations of carriers.

After more than twenty years of designing, building and selling process carriers in this industry I have seen fabricators embraced for their ability to solve problems expensive equipment could not solve and I have seen fixtures fall short of their anticipated performance. Many issues can be scientifically and relatively inexpensively solved by well designed process carriers. Like all things in the world there needs to be a balance. Process Carriers have not solved all PCB Assembly issues and neither have equipment manufacturers.

In conclusion, some fabricators have designed and built some successful alternatives for PCB assembly. Most competent fabricators will tell their customers the limitations of fixturing and have already set up guidelines for successful PCB assembly processes.

Special thanks to Gary Dick, Process Engineer at Celestica-Canada for providing valuable information on his experience with fixtures and equipment.

For more information, contact Mark Beesley at MB Manufacturing

1 Gwinnup Road, Blairstown, NJ 07825

Phone: 908.362.5588

Fax: 908.362.5115

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.